Khatello e phahameng ea lefu la ho lahla ke mokhoa o etsang hore tšepe e nang le metsi kapa halofo ea metsi e tlatse mokoti oa hlobo ea lefu la ho lahla ka lebelo le phahameng ka khatello e phahameng, le mefuta le ho tiisa tlas'a khatello ea ho fumana ho lahla.

1.Ts'ebetso ea ho lahla khatello e phahameng

1.1

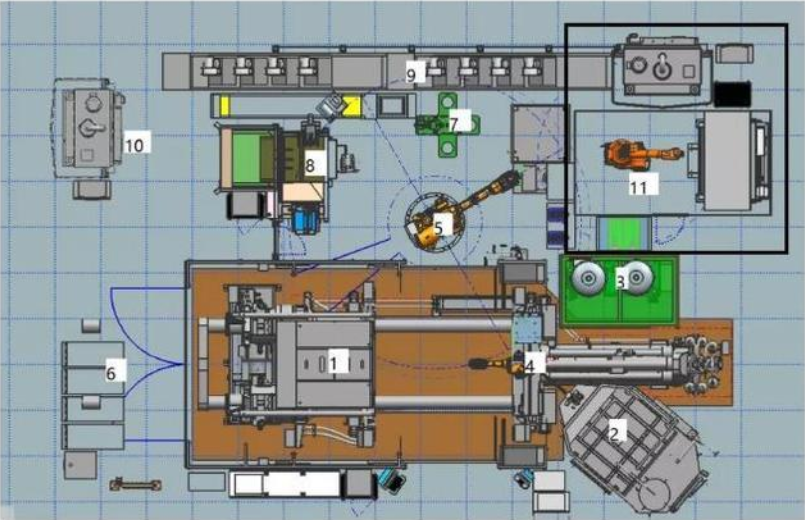

Hajoale, sehlekehleke se akaretsang sa die-casting se tla nahana ka tlhophiso e latelang; Mochini oa ho lahla o nang le vacuum, sebōpi sa ho boloka mocheso se na le sistimi ea ho lahla, sehlahisoa se nang le mofuta oa sistimi ea ho fafatsa, ho khutsufatsa nako ea ho fafatsa, roboto ho nka likarolo, mokotla oa slag, ho seha khoutu le mosebetsi o mong, ho itšeha ho qetela tsamaiso ea liheke; Sehlekehleke sa die-casting se ka boela sa ntlafatsoa bakeng sa ho hloekisa ka mokhoa o ikemetseng tlas'a maemo a phahameng a phahameng.

1.2

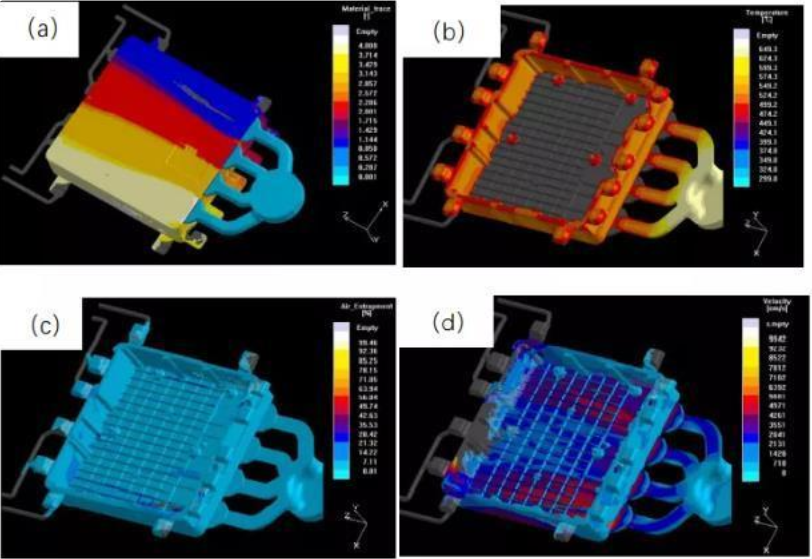

Tlhahlobo ea CAE e sebelisoa haholo indastering ea ho lahla lefu, e emetsoeng ke PROCAST, MAGMA, flow-3D, joalo-joalo Ho ea ka liphello tsa lipalo tsa ho tlatsa phallo le kabo ea lebelo, papiso e ka bolela esale pele ka nepo liphoso tse kang ho ngolisa, ho kenyelletsa le ho tlatsa hampe, e leng ho ntlafatsang haholo lihlahisoa le ho boloka litšenyehelo tsa sepheo haholo. Ke sesebelisoa se molemo haholo sa ho qapa ka potlako le ka saense tsamaiso eohle ea ho lahla (heke, sprue le tanka ea ho phalla, joalo-joalo) bakeng sa lefu la lefu. Ntlafatsa litekanyetso tsa ts'ebetso ea ho lahla, fokotsa palo ea tlhahlobo ea hlobo, fokotsa litšenyehelo tsa ho lahlela, ntlafatsa boleng ba sehlahisoa. Software ea CAE e ne e sebelisetsoa tlhahlobo e akaretsang ea ho tlatsa, ho tiisa, kabo ea porosity le litlaleho tsa kabo ea lebelo

1.3 Ho sebelisoa ha vacuum die casting

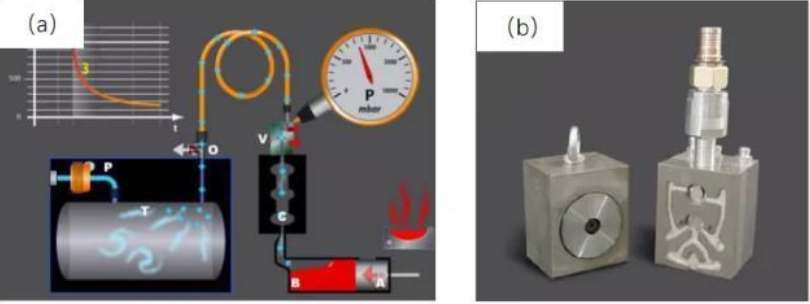

Ka phepelo e tsoelang pele ea litlhoko tsa boleng ba sehlahisoa, ho sebelisoa ha vacuum ho rarolla bothata ba ho tlatsa le ho tiisa moea oa li-castings ho entsoe hantle, 'me valve ea vacuum e sebelisoa hangata, valve ea vacuum e sebelisoang ka ho fetisisa e na le mehaho e' meli e latelang. Setšoantšo sa 3 ke setšoantšo sa moralo oa valve ea vacuum. Joalo ka mokhoa o tloaelehileng oa ho lahla lefu, kamora hore metsi a aluminium a kene ka phaposing, vacuumization e qala ho qala. Joale, ha mochine oa die casting o qala ka lebelo le phahameng, matla a kinetic a metsi a aluminium a tšeptjoang ho ama poleiti ea selemo ea valve ea vacuum. Ha o sebelisa valve ea mochini oa vacuum, hangata e koaloa ha ho futhumatsa hlobo. Ha preheating e felile, valve ea vacuum e ka sebelisoa feela ha lebelo le phahameng le khatello ea khatello e qala. Mochine oa vacuum valve o na le melemo ea tšebeliso e bonolo, empa ho nepahala ha ts'ebetso ea vacuum valve ho phahame, 'me litšenyehelo tsa vacuum valve li batla li phahame. Setšoantšo sa 4 ke setšoantšo sa moralo oa valve ea hydraulic vacuum. Molao-motheo oa valve ea mochini oa vacuum o tšoana. Ha punch e qala, sekheo se qala, empa molao-motheo oa ho koala valve ea vacuum o fapane. Ha valve ea hydraulic vacuum valve e atisa ho qala ka lebelo le phahameng, mofuta o romelloa tsamaisong ea hydraulic ea vacuum valve ka nako e le 'ngoe,' me valve ea vacuum e koetsoe. Litsenyehelo tsa hydraulic vacuum valve li batla li le tlase, empa li hloka hore mekhahlelo ea "die casting process" le moralo oa hlobo li ts'oane, ho seng joalo metsi a aluminium a shoang ka har'a valve ea vacuum e tla baka thibelo.

2.Litšoantšiso

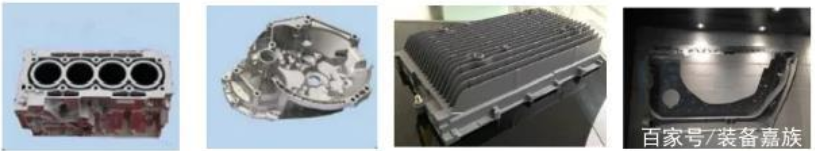

Hajoale, lihlahisoa tsa aluminium alloy die casting li arotsoe ka mekhahlelo e meraro ho latela palo. Sehlopha sa pele ke koloi, sethuthuthu, khetla ea phetisetso ea enjene e emeloang ke enjene ea enjene, 'mele oa silinda joalo-joalo. Mofuta oa bobeli ke khetla ea setsi sa setsi le khetla ea filthara e emeloang ke puisano ea marang-rang, 'me mofuta oa boraro ke sebopeho sa' mele se nang le litlhoko tse phahameng tsa ts'ebetso ea mochini. Joalokaha ho bontšitsoe setšoantšong, ke sehlahisoa se tloaelehileng sa aluminium alloy die casting:

3.Qetello

Aluminium alloy e na le matla a khethehileng a phahameng le ho hanyetsa ho hotle ha kutu, motlakase o motle haholo. Tlas'a tikoloho ea sechaba ea ho boloka matla le phokotso ea mosi le ts'ireletso e tala ea tikoloho, aluminium alloy die casting e tsoetse pele ka potlako Chaena. Ke lumela hore haufinyane, lihlahisoa tsa alloy aluminium li tla ba tse fapa-fapaneng haholoanyane. The deformation ka sehloohong e likarolong tse latelang; 1) Ka nts'etsopele ea lihlahisoa, e tla khanna nts'etsopele ea lisebelisoa tse ncha tsa aluminium alloy, tse kang: conductivity e phahameng ea mocheso, matla a phahameng le tataiso e phahameng ea toughness; 2) lisebelisoa tse ncha tsa alloy alloy le tsona li tla nts'etsapele nts'etsopele ea theknoloji e ncha ea ho lahla lefu, joalo ka ts'ebetso ea semi-solid die casting, mochini o phahameng oa vacuum suction casting 3) nts'etsopele ea theknoloji le eona e tla fana ka lisebelisoa, lisebelisoa tse thusang li behiloe litlhoko tse phahameng. , joalo ka: mochini o moholo oa ho lahla, mochini oa mocheso oa shoa, lisebelisoa tsa ho fafatsa, ho lokolla hlobo mochini o ts'oanang, mochini oa vacuum, mochini o batang, taolo ea mocheso oa hlobo le sistimi ea ho lemoha, jj.

Nako ea poso: May-19-2022